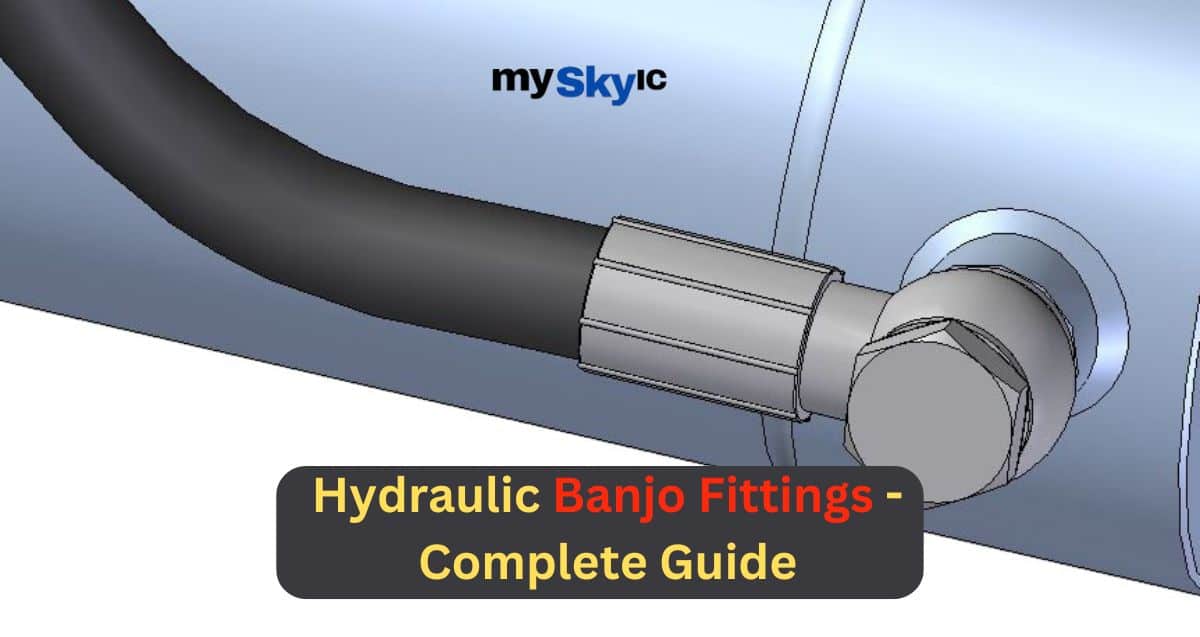

Banjo fittings are specialized fluid transfer connectors designed to allow smooth, leak-proof flow in hydraulic, pneumatic, and fuel systems, often used for tight spaces or applications where space-saving is crucial. They consist of a hollow, round fitting connected to a pipe or hose, typically with a bolt or screw in the center that secures the assembly, creating a strong and secure joint. Banjo fittings are most commonly found in automotive systems, hydraulic machinery, and fuel transfer lines.

Table of Contents

What Are Banjo Fittings?

Banjo fittings, also known as banjo bolts or banjo connections, derive their name from the fitting’s shape—it resembles a banjo instrument. The fitting comprises two key components: a circular hollow section (the “banjo”) and a bolt or screw that passes through the banjo’s center.

These fittings are widely used in hydraulic systems, fuel lines, and brake systems because they allow the transfer of fluids at high pressures while minimizing the risk of leaks. Banjo fittings can also swivel, allowing them to be used in tight or compact spaces where traditional fittings would not fit.

Key Components of Banjo Fittings:

- Banjo Bolt: A hollow bolt that allows fluid or gas to pass through. It typically has one or two holes drilled through the side to permit flow.

- Banjo Housing: The round component through which the banjo bolt passes. It often includes an inlet for attaching hoses or tubing.

- Copper or Aluminum Washers: These washers ensure a leak-proof seal by compressing between the bolt head and the housing.

How Banjo Fittings Work:

Banjo fittings operate by allowing fluid to flow through the bolt’s hollow shaft and out through the drilled side holes. The fluid then continues through the connected hose or pipe. A key feature of banjo fittings is their ability to rotate without causing damage to the fitting or hose, which makes them perfect for use in dynamic systems where movement might occur. They provide a reliable and secure connection in systems requiring high-pressure flow, such as hydraulic or fuel lines.

Common Types of Banjo Fittings:

Banjo fittings come in various materials and sizes, but the most common variations include:

- Single Banjo Fittings: Standard design for single-line systems, often used in fuel and brake lines.

- Double Banjo Fittings: Designed to connect two hoses or pipes, allowing dual fluid lines to flow through a single connection.

- 90-degree Banjo Fittings: The fitting is angled at 90 degrees to allow connection in tight spaces where straight connections may not fit.

- Stainless Steel Banjo Fittings: Preferred in applications requiring corrosion resistance and strength, such as marine or high-performance automotive systems.

- Aluminum Banjo Fittings: Lightweight and commonly used in performance applications where weight is a concern.

Where Are Banjo Fittings Used?

Banjo fittings are highly versatile and can be found in several industries and applications, including:

- Automotive Brake Systems: Banjo fittings are often used in braking systems, especially for high-performance or racing vehicles, as they ensure a secure and leak-proof connection.

- Hydraulic Machinery: Banjo fittings allow high-pressure hydraulic fluid to flow smoothly and are used in tractors, construction equipment, and industrial machinery.

- Fuel Systems: You’ll find banjo fittings in fuel transfer systems where reliable, high-pressure fluid flow is necessary. They are common in diesel engines and fuel injection systems.

- Pneumatic Systems: Banjo fittings also serve in air systems for equipment like compressors, air brakes, or other pneumatic tools where precise pressure control is required.

Advantages of Banjo Fittings:

- Compact Design: Their round shape and ability to swivel make them ideal for tight spaces or systems that need frequent maintenance or adjustments.

- Leak-proof Seals: When installed properly, with high-quality washers, banjo fittings create extremely reliable seals that prevent leaks.

- High-Pressure Compatibility: Banjo fittings can handle high-pressure fluids, making them ideal for hydraulic and fuel systems.

- Ease of Installation: Banjo fittings are relatively easy to install, and their design allows for flexible routing of hoses or pipes.

Installation Tips for Banjo Fittings:

To ensure a leak-proof installation, follow these guidelines:

- Use Fresh Washers: Always replace copper or aluminum washers when reinstalling banjo fittings. Old washers can become deformed and fail to create a proper seal.

- Torque Properly: Over-tightening or under-tightening banjo bolts can lead to leaks or damage. Always torque to the manufacturer’s specifications.

- Check for Debris: Ensure that all components are clean before installation, as any debris can compromise the seal.

FAQs About Banjo Fittings:

What are the common materials for banjo fittings?

Banjo fittings are typically made from materials such as stainless steel, aluminum, or brass, depending on the application. Stainless steel is preferred for high-pressure or corrosive environments, while aluminum is chosen for lightweight applications.

Are banjo fittings suitable for brake systems?

Yes, banjo fittings are commonly used in automotive brake systems, especially in high-performance vehicles. They offer a reliable, leak-proof connection for hydraulic brake lines.

What is the main advantage of a banjo fitting?

The primary advantage of a banjo fitting is its ability to swivel and work in tight spaces, making it ideal for complex fluid transfer systems.

Conclusion:

Banjo fittings are an essential component in many industries, from automotive to hydraulic machinery. Their unique design allows for fluid transfer in high-pressure environments while minimizing leaks, and they are especially valuable in situations where space is limited. Whether you’re dealing with a car’s brake system or an industrial machine, understanding how to properly select, install, and maintain banjo fittings is crucial for optimal system performance.

For a strong, reliable, and leak-proof connection, banjo fittings are an indispensable part of modern fluid transfer systems.